Durable Super Wear® Plates for Hard-Surfacing Projects

Chromium Carbide Overlay – Wear- and Abrasion-Resistant Plate

In 1977, Alabama Hardsurfacing, Inc. pioneered the hard-surfacing of the A-36 steel plate for wear parts. Today, this process is called a chromium carbide overlay plate. Super Wear® Plate has saved our customers money by minimizing downtime and parts usage.

Alabama Hardsurfacing, Inc.’s unique overlaying process produces one of the best chromium carbide plates in the world. Using a low carbon steel base plate, Super Wear® Plate can easily be formed and welded to most structural surfaces. Super Wear® Plate material gets its wear properties through its maximum carbide concentration and carbide alignment. That why Super Wear® Plate is the best chromium carbide overlay plate available on the market.

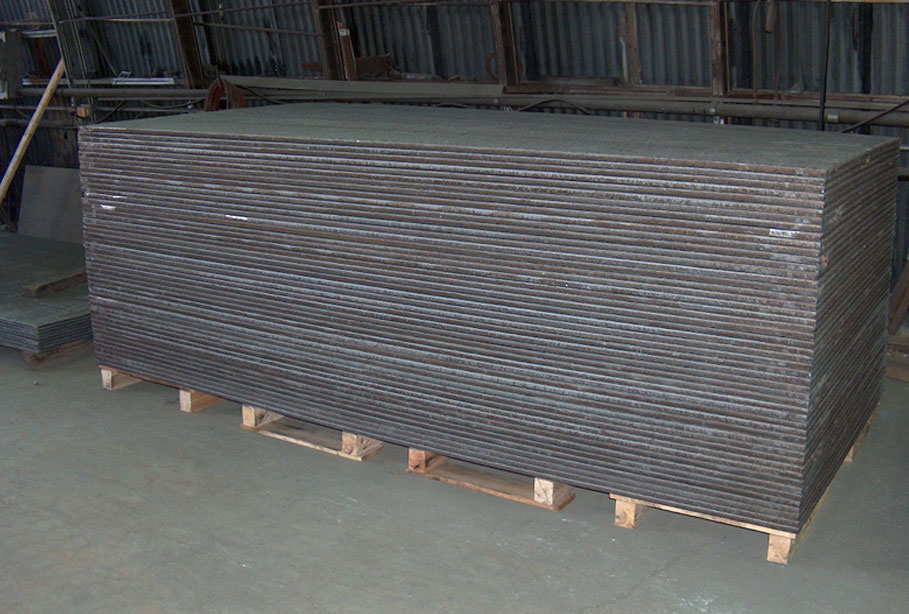

Super Wear Plate is manufactured in 5’ x 10' plates, as well as 6' x 10' plates with a single overlay pass or double overlay pass and from 3/8” thick to 1” thick. Super Wear® Plate can be used for any kind of wear problems. Our customers tell us that Super Wear® Plate will last six times longer than the AR plate or T-1 plate.

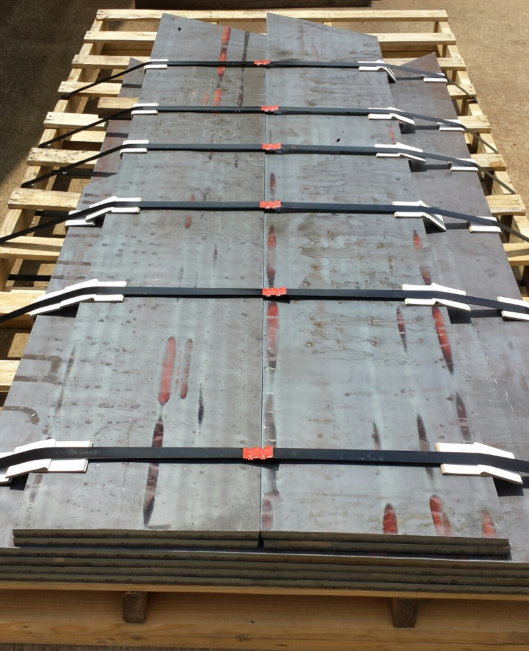

In 1975, Alabama Hardsurfacing, Inc. began rebuilding steel and manganese crusher hammers. In fact, it has become one of our specialties. Our rebuilt hammers, with our custom alloys, enable us to guarantee a longer life than our competitors. Alabama Hardsurfacing, Inc. is a vendor for some of the largest companies in the world.

Our customer base is :

Our price includes the following :

We will furnish a list of satisfied customers upon request.